Model Capacity Size Speed Motor / Voltage Dimensions / Weight Variable Length: 192" Width: 84" Height: 48" Passline: 33" Weight: 5,400 lbs.

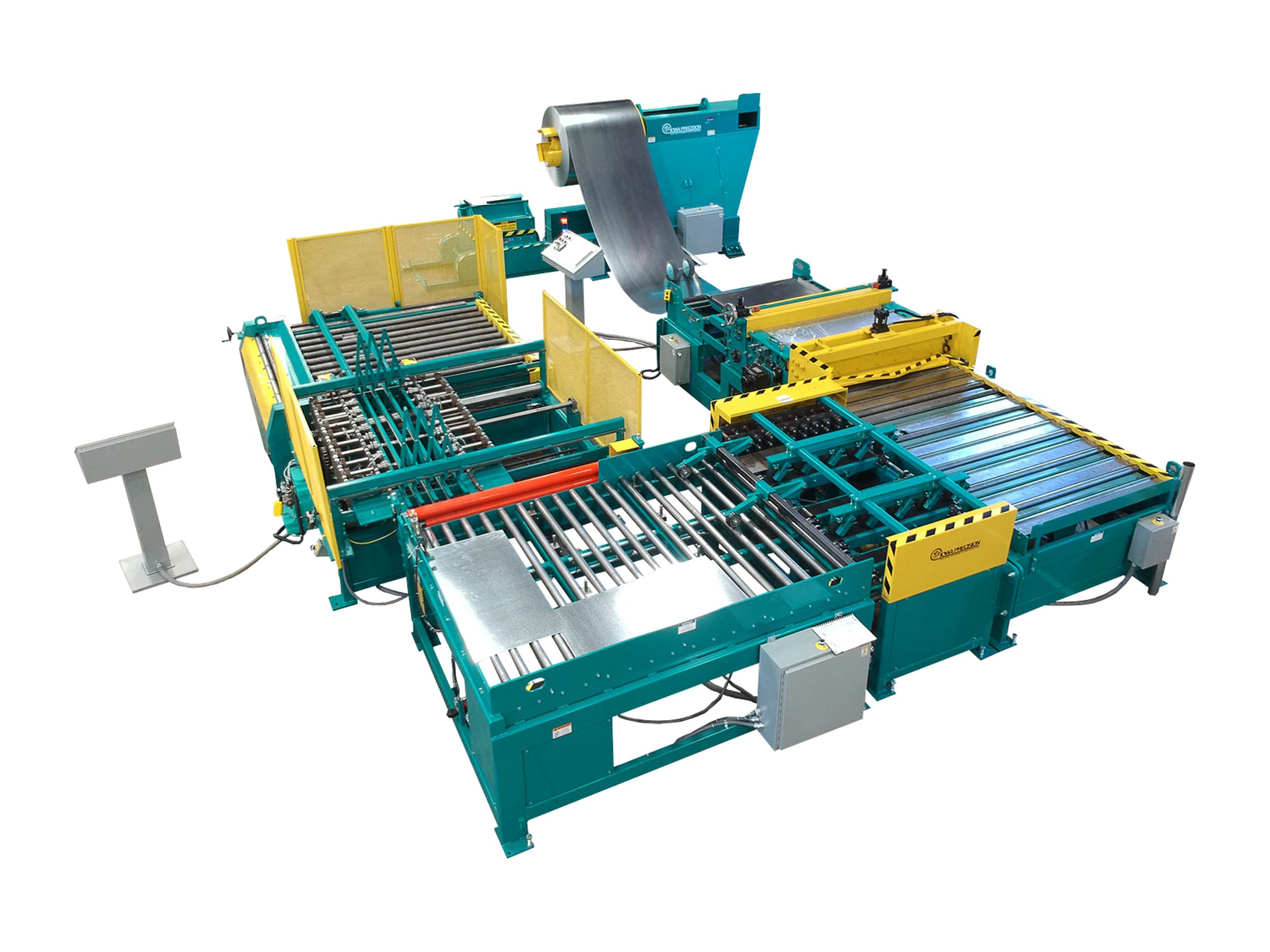

Iowa Precision Automated Furnace Pipe Rolling System

-

Iowa Precision Automated Furnace Pipe Rolling System

-

Iowa Precision Automated Furnace Pipe Rolling System

-

Iowa Precision Automated Furnace Pipe Rolling System

-

Iowa Precision Automated Furnace Pipe Rolling System

-

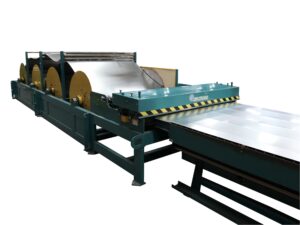

Iowa Precision Automated Furnace Pipe Rolling System | Round Pipe Output

-

Iowa Precision Automated Furnace Pipe Rolling System | Oval Pipe Output

-

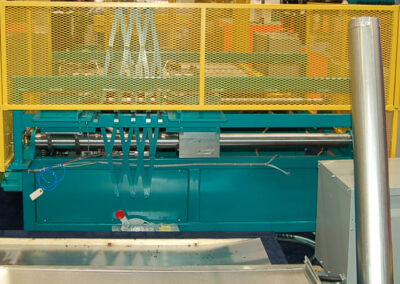

Iowa Precision Automated Furnace Pipe Rolling System

Iowa Precision Automated Furnace Pipe Rolling System

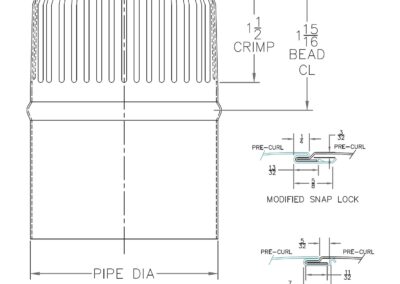

Iowa Precision | Automated Furnace Pipe Rolling System

Iowa Precision | Automated Furnace Pipe Rolling System

Iowa Precision | Automated Furnace Pipe Rolling System