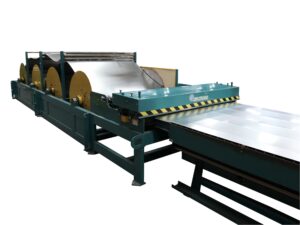

Lockformer Vulcan Fiber Laser Cutting System

The Lockformer® Vulcan® Fiber Laser Cutting System is the next evolution in cutting systems from Lockformer. Using over 30 years of sheet metal cutting experience, we’ve designed the Lockformer Vulcan Fiber Laser Cutting System to meet the specific needs of sheet metal fabricators to help take your operation to the next level. Faster, more precise cutting, better quality parts, coil feeding capability, quicker access to cut parts and many more features all designed to improve the productivity and profitability of your fittings operation while setting the standard for safety (accession number and coveted Class 1 safety rating from the Food and Drug Administration).

Part of the family of Lockformer Vulcan Cutting Systems which also includes:

Features

The Lockformer Vulcan Fiber Laser Cutting System was designed with the needs of sheet metal fabricators in mind and is the optimal system for producing sheet metal HVAC fittings.

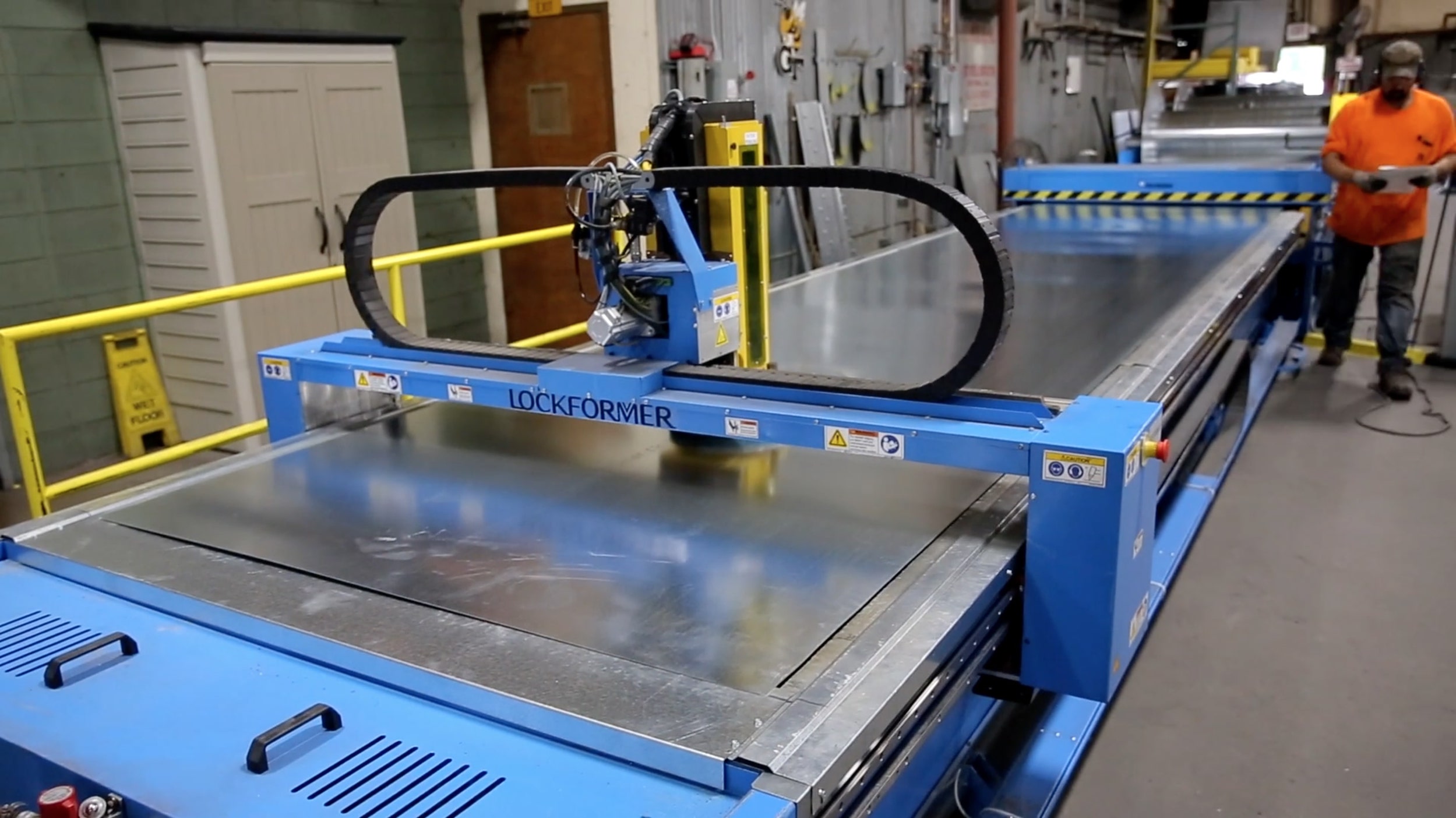

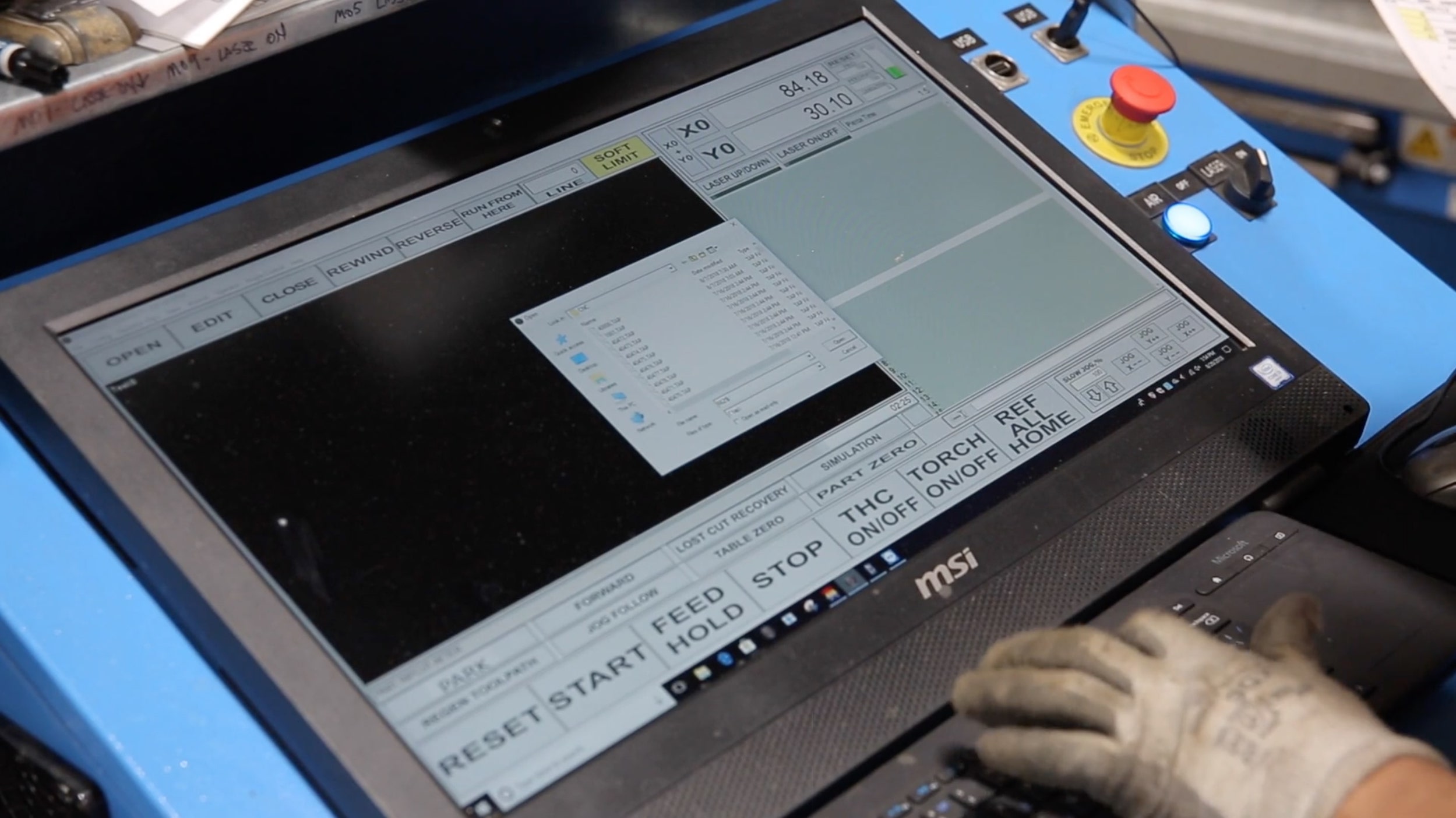

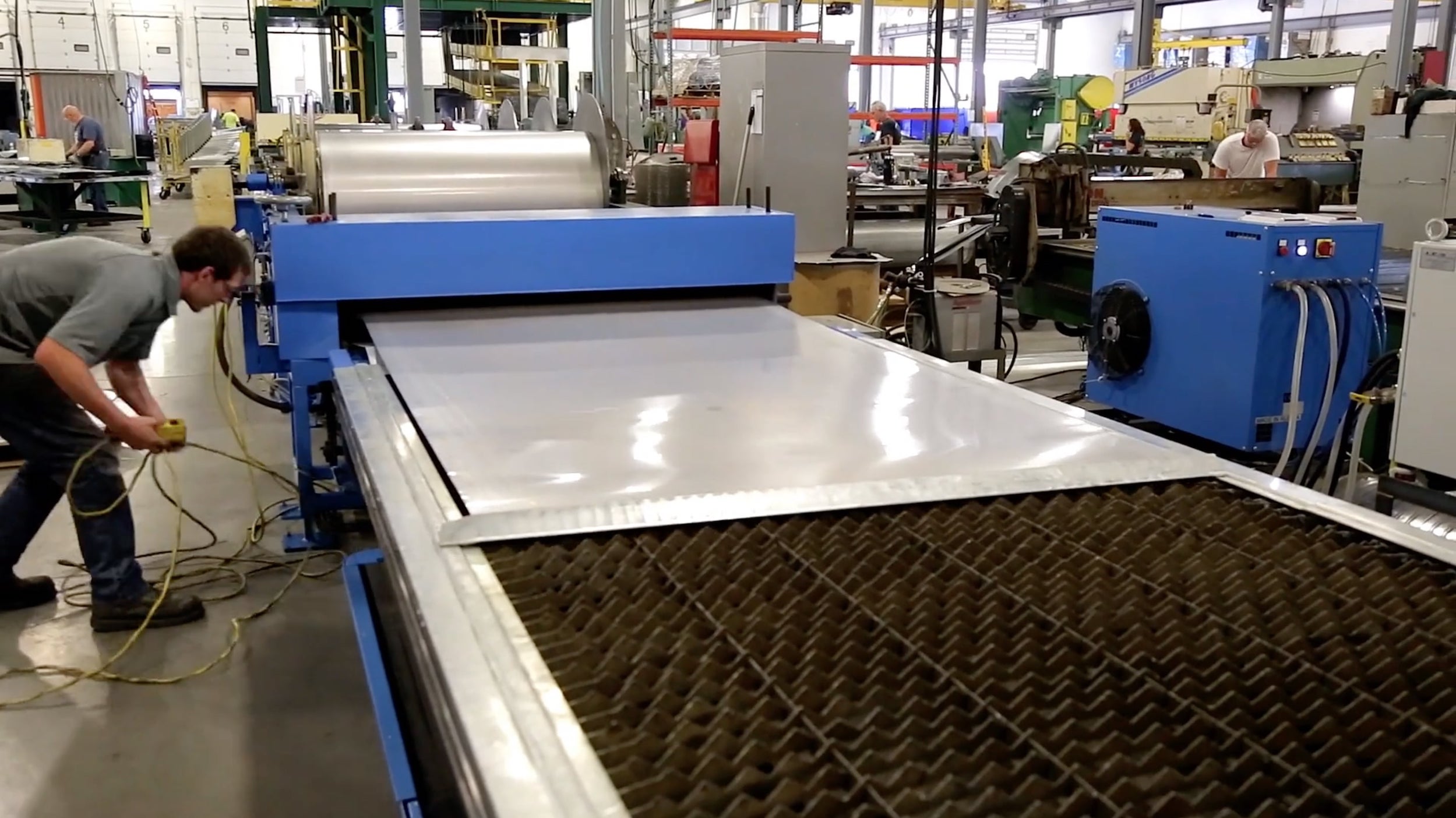

The Fiber Laser offers a cut speed up to 1,200 inches per minute (28 m/min) on 0.120″(3 mm) or 0.135″(3.5 mm) mild steel — that’s 2-1/2 to 3X faster than a conventional plasma cutter with a cut quality like that of a high definition plasma cutter on mild steel and stainless. And because the Fiber Laser uses less heat than a plasma cutter, product edges are not hardened and will cause less wear and tear on other machinery. With a standard 5’ x 10’ table with an option of 5’ x 20 Lockformer Vulcan Fiber Laser can be coil fed or sheet fed. The Lockformer Vulcan Fiber Laser features an exclusive patent-pending open architecture design (no enclosure) which provides access to parts directly from the table, eliminating the need for a pallet shuttle system, and a zoned exhaust that produces minimal fumes. Equipped with a Windows 10® Professional PC with 19″ Monitor and Printer, the Fiber Laser can be integrated with the Lockformer most CAD to CAM software systems for maximum shop productivity and seamless connectivity with other machines throughout your operation.

Safety Features

The Lockformer Vulcan® Fiber Laser Cutting System obtained an accession number and a coveted Class 1 safety rating from the Food and Drug Administration (FDA). The system features a Class 1 fiber laser with open architecture design which not only allows for easy integration into existing workflows and customization according to specific production needs but also promotes adaptability for future technological advancements. And the patented shroud design in the system further elevates its operational safety and cutting precision, ensuring high-quality results while mitigating hazardous risks. These innovative features collectively simplify maintenance procedures, significantly reducing downtime and bolstering continuous operational efficiency.

Accession Number and Class 1 Rating for Fiber Laser Cutting System

Reflecting the highest safety and quality standards, the FDA’s thorough evaluation process includes meticulous design and manufacturing process reviews, extensive performance testing, and strict compliance with laser safety standards. This leads to the assignment of an FDA accession number and a Class 1 safety rating, underscoring the system’s reliability, effectiveness, and adherence to rigorous safety protocols.

Comprehensive Laser Safety

Combining a Class 1 fiber laser with a patented shroud design ensures maximum safety for operators and surrounding personnel by eliminating any hazards within a controlled environment. This configuration minimizes the risk of exposure to hazards, promoting a secure work environment, and compliance with safety regulations. The Class 1 fiber laser is a low-powered device that is considered safe from all potential hazards during normal use.

Minimized Exhaust Emissions

The Fiber Laser Cutting System operates completely on compressed air with minimal to zero exhaust. The use of compressed air significantly reduces harmful emissions that are often associated with conventional cutting methods. By eliminating the need for gases or other chemicals, this system presents an environmentally responsible solution, ensuring a cleaner and safer working environment. This aspect is particularly vital in today’s industry, where environmental impact and worker safety are paramount. Chemicals taken out.

Interoperability

Exclusive patent-pending open architecture fosters interoperability with other machinery and equipment within a manufacturing environment. The open architecture design also allows for the use of coil feed machines eliminating the need to load material by hand maximizing cutting productivity. This integration capability promotes streamlined workflows, increased automation, and improved overall efficiency.

Enhanced Performance and Safety

Lockformer’s patented shroud design of the Fiber Laser Cutting System contributes to both performance and safety during the cutting process. The design enhances operator safety by containing potentially hazardous materials and preventing them from escaping into the surrounding environment. Additionally, by effectively managing airflow and debris, the shroud minimizes the risk of contamination and ensures consistent cutting quality.

Optimized Cutting Quality

The combination of open architecture and the patented shroud design ultimately leads to optimized cutting quality. With the ability to integrate advanced software systems and customize cutting parameters, operators can achieve precise, high-quality cuts across a wide range of materials and thicknesses. The shroud design further enhances cutting consistency by maintaining a clean and controlled cutting environment, resulting in superior finished products with minimal defects or imperfections.

Direct Access

The open architecture of the Fiber Laser Cutting System allows workers to have direct access to the cutting table, eliminating the need for a pallet shuttle system. This enables operators to efficiently remove parts directly from the table, streamlining the production process, and reducing the reliance on additional equipment for part retrieval.

Ease of Maintenance and Serviceability

Open architecture simplifies access to internal components, making maintenance and servicing tasks more straightforward and efficient. This accessibility reduces downtime for maintenance, minimizing disruptions to production schedules, and ensuring continuous operation. Similarly, the design of the patented shroud facilitates easy cleaning and upkeep, further contributing to the system’s overall reliability and longevity.

Versatility and Compatibility

The open architecture of this fiber laser cutting system allows for compatibility with various software systems and customization options. This flexibility enables seamless integration into existing production setups and workflows, regardless of the specific requirements or software preferences of the user. It also facilitates the system’s adaptability to future technological advancements or changes in production needs.

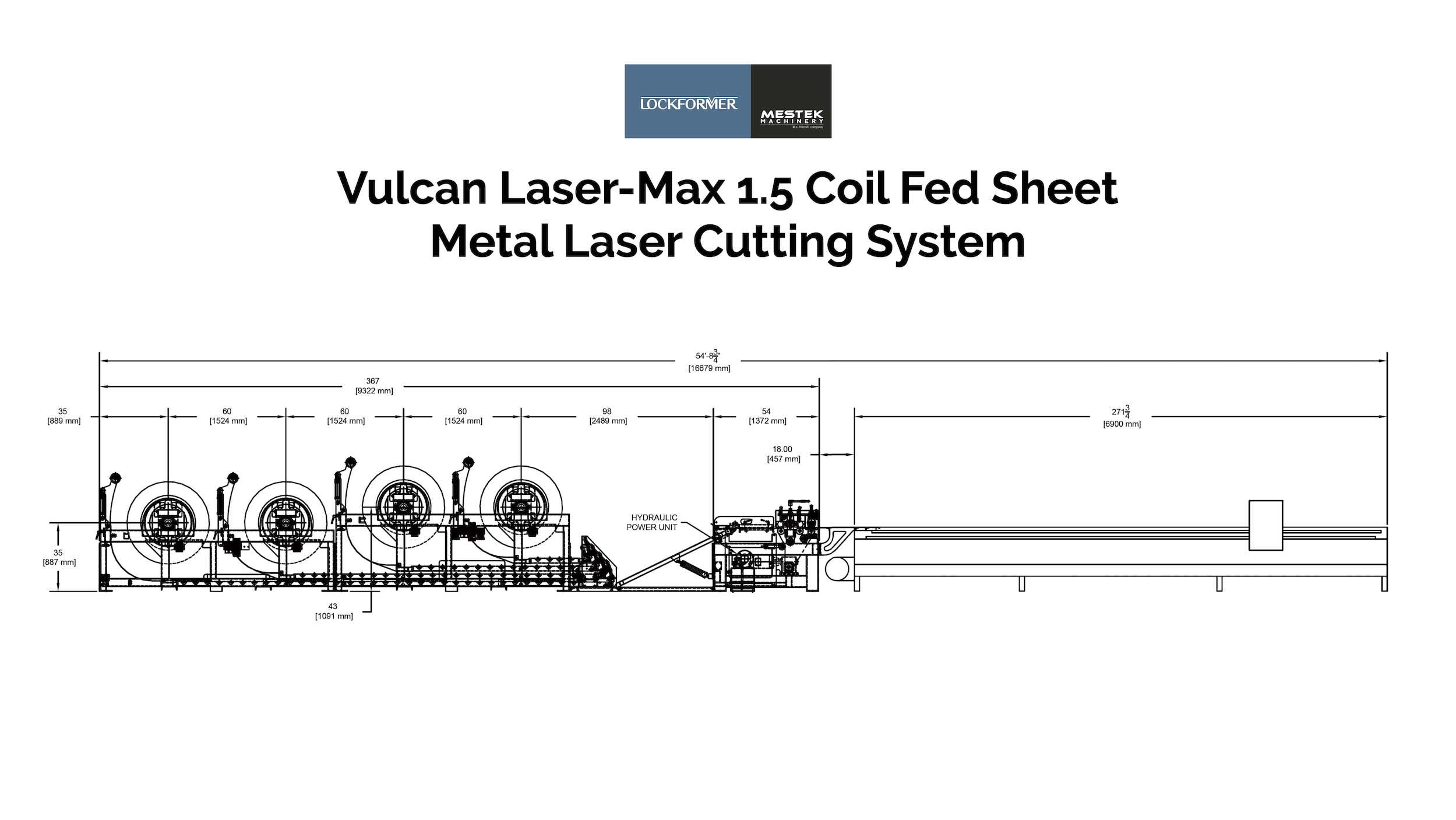

Specifications

Model | Software / Computer System | Machine Control | Cutting / Plasma Unit | Cutting Capacity | Speed | Cutting Area and Table Capacity | Dimensions / Weight |

Lockformer Vulcan Fiber Laser 1.5 Coil Fed Sheet Metal Laser Cutting System | Windows 10® Professional PC with 19" Monitor and Printer | Mach 3 and Color Graphic Industrial Touch Screen | 1.5 KW Standard | 0.120" (3 mm) or 0.135" (3.5 mm) mild steel cutting capacity based on laser resonator selected | Positioning speed and max cutting speed are the same at 1,100 ipm (28 m/min) on thinner materials (26 ga or 0.4 mm) | Standard: 5' x 10' | Length: 168" |