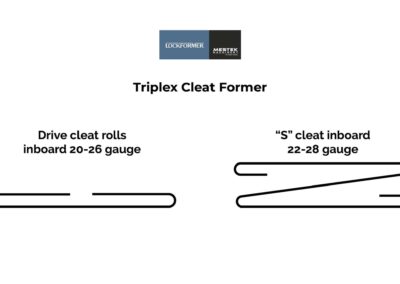

Lockformer Triplex Cleat Former

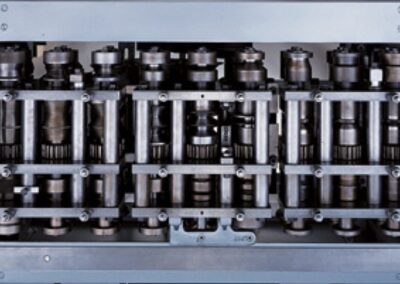

The flexible Lockformer Triplex Cleat Former is designed for super high productivity in the fabrication of inboard cleats. The machine design has two inboard and two outboard forming positions allowing bearing support on both sides of the profile. The top plate and roll assembly are split into three zones with each having special design details like knurled rolls and angled guides to keep material moving through the machine in a straight line. These zones also can be adjusted by the operator to meet the requirements of a wide variety of gauges.

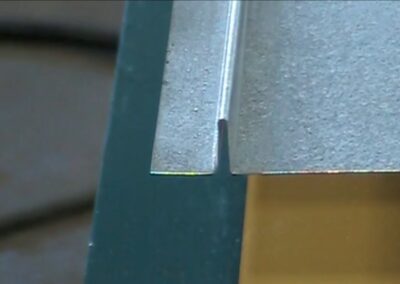

With nine (9) forming stations, the Triplex Cleat Former can form multiple gauge sheet metal into “S” and drive cleats on the inboard forming positions and up to twelve (12) auxiliary roll set profiles on the outboard forming positions at speeds averaging 100 fpm. Standard with Lockformer quality construction, this machine has a 5HP industrial motor, high precision needle-type bearings, heavy 3/4″ chassis plate, case-hardened and ground roll shafts, and an arc-welded steel stand protected with Lockformer’s top quality primer and paint finish.

Model Capacity Depth of Pocket / Size Other Speed Motor / Voltage Dimensions / Weight 22-28 gauge for "S" cleat profile and 20-26 gauge for drive cleat profile "S" cleat width 1-1/16" Extended shafts for mounting auxiliary rolls 100 feet per minute Length: 60"

Drive cleat width 1-1/8"

Width: 24"

Height: 40"

Passline: 32-1/2"

Weight: 850 lbs.

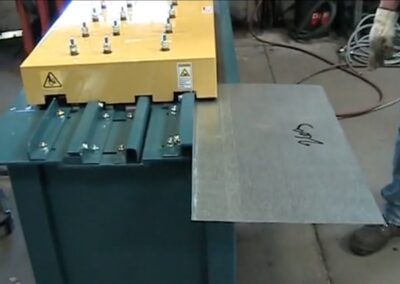

Lockformer | Triplex Cleat Former | Demonstration