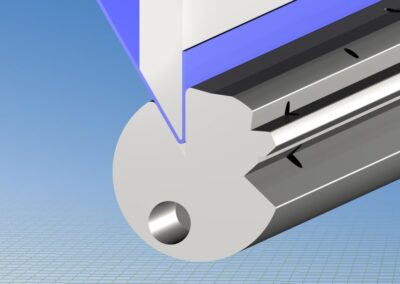

Roto-Die Metal Forming Machines and Equipment

Roto-Die® hydraulic sheet metal bending brakes are the industry standard in HVAC and metal fabrication shops and are known for their versatility, cost-effectiveness, and productivity. With specialized heavy-duty hydraulics, our sheet metal brakes can make accurate bends on 26 ga. to 10 ga. steel from 24″ up to 12′ in length. Below are all the machine and equipment solutions available from Roto-Die for your review — and please don’t hesitate to reach out if you have a particular application or operational requirement that might require a customized solution… we’d love to help.

Featured Roto-Die Machine

Roto-Die Metal Forming Machines and Equipment

Machine / Equipment Types

- All

- Uncategorized

- Coil Metal Processing Machinery and Equipment

- Flexible Fabrication Machinery and Equipment

- HVAC Insulation Cutting Machinery and Equipment

- HVAC Rectangular Duct and Fittings Fabrication Machinery and Equipment

- HVAC Round and Oval Duct and Fittings Fabrication Machinery and Equipment

- HVAC Spiral Duct and Fittings Fabrication Machinery and Equipment

- Metal Cutting Machinery and Equipment

Schedule a 1-on-1 Consultation with a Roto-Die Technical Advisor

For over 45 years, Roto-Die’s unique hydraulic sheet metal bending brakes have been regarded as an industry standard in HVAC and metal fabrication shops throughout the United States. Each sheet metal brake is a versatile, economical, productive tool satisfying a wide range of sheet metal bending and forming needs. Looking to improve your productivity and profitability of your HVAC duct and fittings fabrication operation? Looking for a solution to address a particular application? Schedule a no obligation, 1-on-1 consultation with a Roto-Die Technical Specialist today and let us develop a customized solution to address the specific needs of your operation.

We're Here to Help

Have questions about Roto-Die machinery and equipment? Looking for help on a unique application? Need help with a budget estimate to determine overall equipment costs to evaluate if your project can be justified? Please don’t hesitate to reach out — we’d love to help.